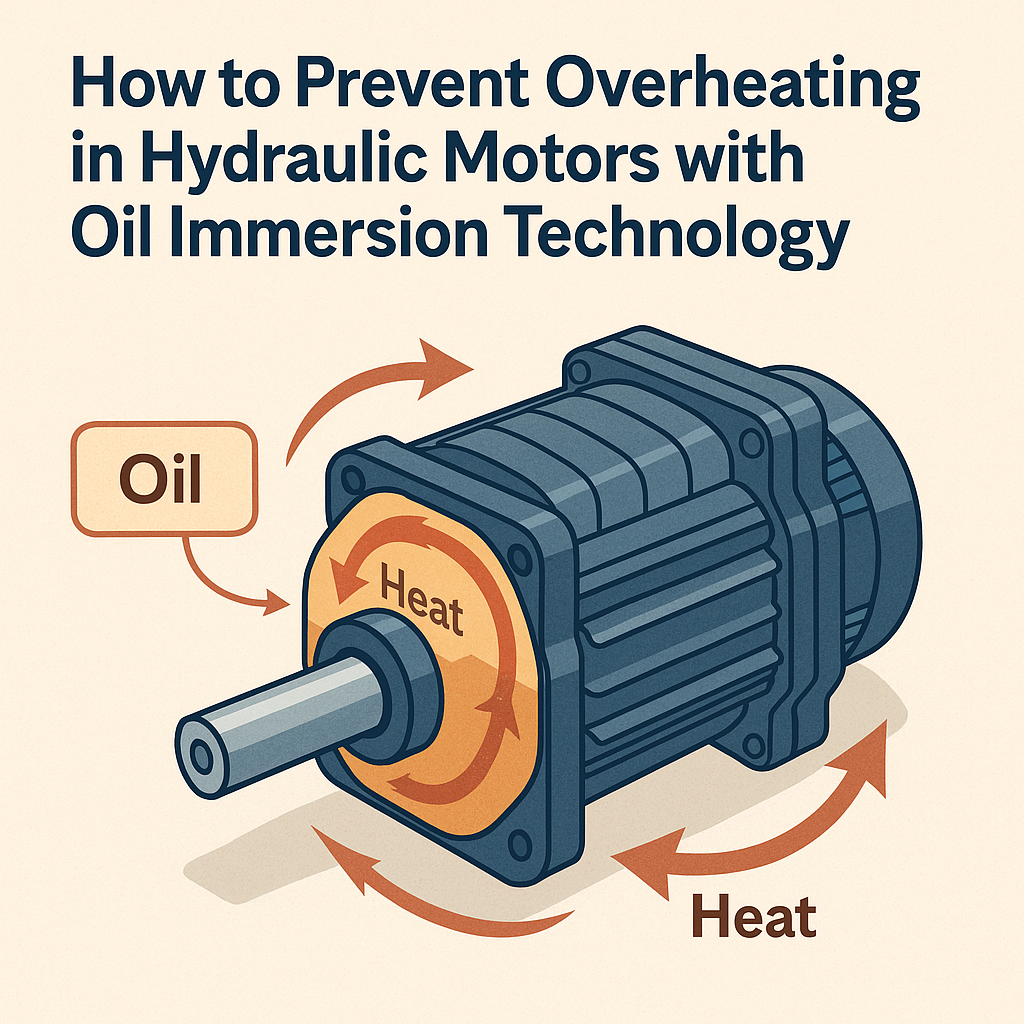

Overheating is one of the most common and damaging issues in hydraulic systems. Excessive heat can cause premature wear, reduced efficiency, and complete motor failure. However, oil immersion technology offers a reliable and efficient solution to mitigate this problem.

In this blog, we’ll explore how oil immersed hydraulic motors work to prevent overheating and share key maintenance tips to keep your systems running smoothly.

🔧 Understanding Overheating in Hydraulic Motors

Before we get into the solution, let’s look at the causes of overheating in hydraulic motors:

- Excessive load or pressure

- Inadequate cooling

- Contaminated or low oil levels

- Continuous operation without rest

- Poor motor design or quality

Heat not only degrades hydraulic fluid but also causes seals and components to fail faster. This is where oil immersion makes a big difference.

💡 What is Oil Immersion Technology?

Oil immersion technology involves submerging the motor windings and internal components in hydraulic or lubricating oil. This method enhances cooling, insulation, and lubrication, leading to better heat dissipation and longer motor life.

✅ How Oil Immersed Motors Prevent Overheating

Here’s how oil immersion helps control motor temperature effectively:

- Continuous Heat Dissipation

The surrounding oil absorbs and transfers heat away from internal components, reducing hot spots and overall motor temperature.

- Improved Lubrication

Oil immersion minimizes friction between moving parts, which means less heat is generated during operation.

- Thermal Stability

Oil has a higher heat capacity and retains stable performance under varying temperature loads, keeping the motor cool in continuous or heavy-duty applications.

- Dust & Debris Protection

Sealed oil-immersed motors prevent external dust and debris from interfering with internal cooling mechanisms, unlike air-cooled counterparts.

🛠️ Maintenance Tips to Maximize Cooling Efficiency

To ensure optimal performance of oil immersed hydraulic motors:

- Monitor oil levels regularly – Low oil can cause heat buildup.

- Use high-quality, thermally stable hydraulic oil.

- Change oil periodically to avoid contamination and sludge formation.

- Inspect seals and gaskets to prevent leaks that reduce cooling efficiency.

- Install temperature sensors to detect abnormal rises in temperature early.

📊 Oil Immersion vs. Air Cooling: Efficiency Comparison

| Feature | Oil Immersed Motor | Air Cooled Motor |

| Heat Dissipation | Excellent | Moderate |

| Dust/Debris Protection | High | Low |

| Continuous Operation | Reliable | May Overheat |

| Maintenance Frequency | Moderate | High (due to fan/filter) |

| Noise Level | Lower | Higher |