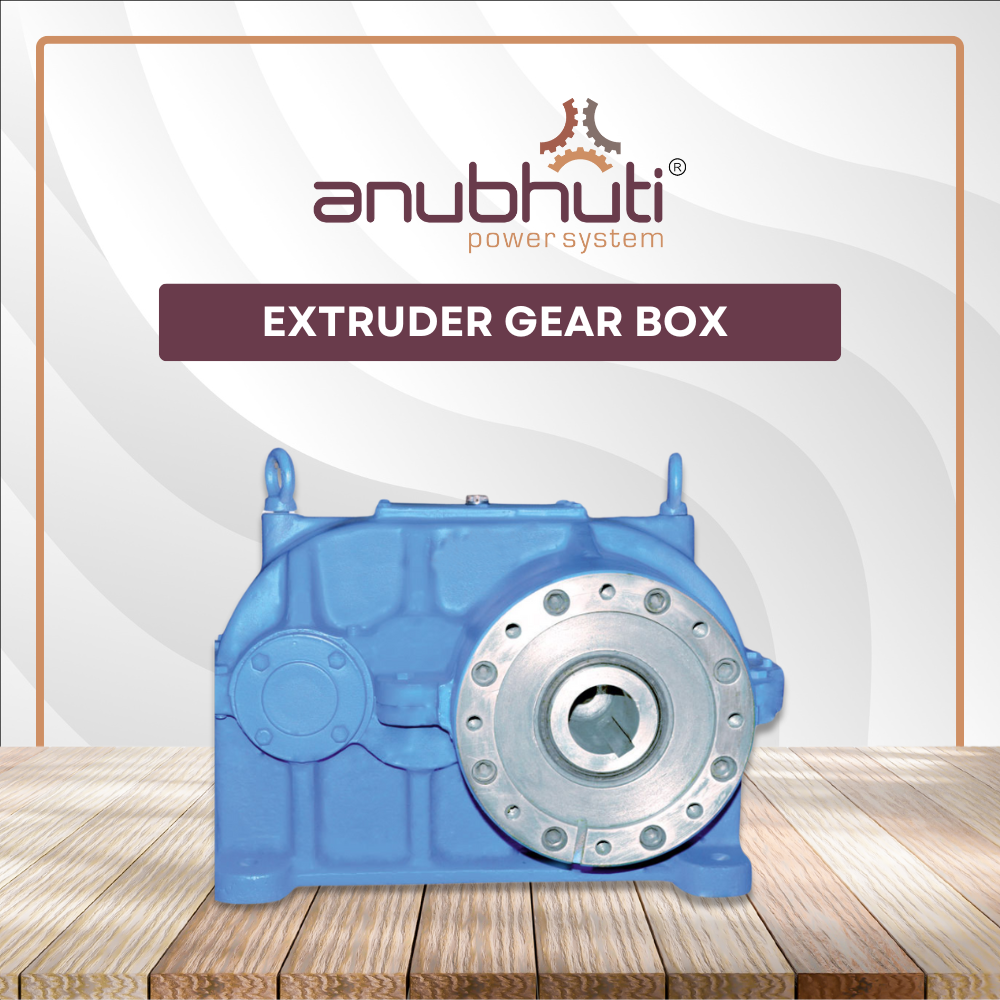

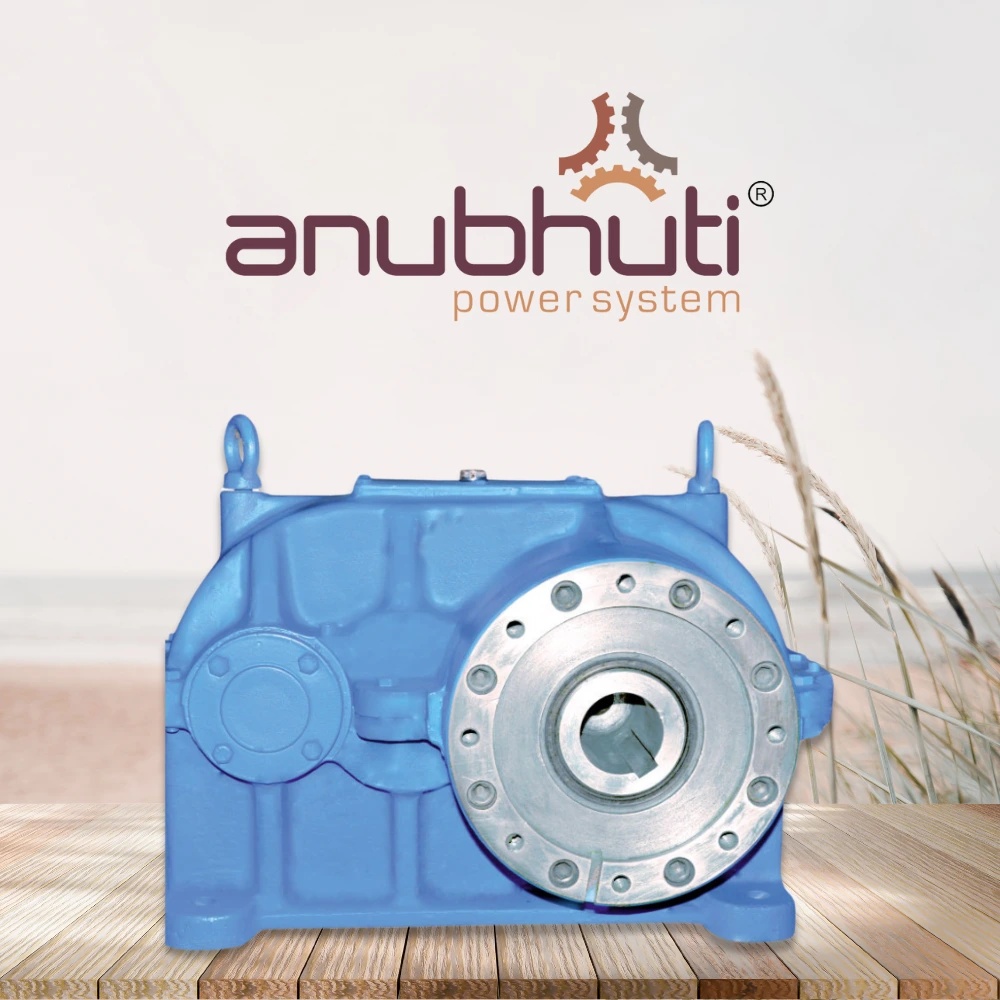

EXTRUDER GEAR BOX

Single Shaft Extruder Gear Units

ANUB HUTI the brand name of since : 1991 the company product are very well accepted all over India.

ANUBHUTI extruder gear boxes in double and single reduction parallel shaft horizontal models are conceived to throughly competent to carry the high torque to absorb the intense axial thrust load through spherical roller thrust bearing This catalogue contains specification dimensions and rating for selection of extruder gear box.

Specifications

GEARS :- Gears and pinion(helical type) are generated from high quality alloy steel with hardening it provides improved wear resistance and fatigue strength These are profile ground to precision grade to ensure high standard of accuracy, Long life and quite running characteristics.

CASE :- Gear Case in built from high quality cast iron. The case in designed for optimal wall thickness.

BEARING AND OIL SEALS :- Bearing from principal manufacturers are utilized throughout. These are selected to endure combined radial and thrust loads High quality oil seals are used to resist the temperature.

LUBRICATION :- Lubrication is complete it in dependent by automatic splash, which, arranges stream of oil for minimum wear and noise Pour oil Before use Fill oil up to midpoint of oil level indicator.

COOLING :- Substantial exterior area is provided for heat dissipation.

All units are fitted with cooling water coil.

TESTING INSPECTION :- All gearboxes are tested up 5 hours on no load to check oil leakage, noise level & temperature.

1. No Alignment Problem

2. Cost Savings

3. Space Savings

4. Power Savings

5. Less Maintenance

6. Easy to Assemble & Dismantle

Quick Contact!

Get Inquiry Now

Key Features of Extruder Gear Box

- High Torque TransmissionEfficiently transfers torque to handle heavy-duty extruder applications with ease.

- Robust ConstructionDurable materials ensure long-lasting performance even under high stress and demanding conditions.

- Compact DesignSpace-saving structure allows easy integration into various extrusion systems and machinery setups.

- Low Noise OperationEngineered for smooth, quiet performance to enhance the working environment's comfort and efficiency.

- High EfficiencyOptimized gear design minimizes energy loss, delivering reliable and consistent power output.

- Customizable RatiosOffers tailored gear ratios to suit specific extrusion requirements for better process control.

Applications of Extruder Gear Box

- Plastic Extrusion

- Rubber Industry

- Food Processing

- Pharmaceutical Industry:

- Chemical Industry

- Cable Manufacturing

- Metal Industry

Extruder gear box Technical Specification

| MODEL | A | B | C | D | E | F | G | H | J | K | L | M | N | P | R | S | T | U |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EXT 110 | 190 | 140 | 430 | 215 | 170 | — | 230 | 80 | 350 | 150 | 180 | 125 | 310 | 25 | 115 | 220 | 8 | 14 |

| EXT 125 | 215 | 155 | 475 | 225 | 200 | — | 260 | 95 | 395 | 170 | 200 | 140 | 340 | 25 | 135 | 220 | 8 | 14 |

| EXT 140 | 240 | 175 | 530 | 240 | 215 | — | 270 | 130 | 440 | 190 | 220 | 160 | 380 | 30 | 200 | 275 | 8 | 14 |

| EXT 160 | 270 | 192 | 590 | 270 | 225 | — | 305 | 135 | 500 | 230 | 270 | 180 | 405 | 35 | 200 | 285 | 10 | 18 |

| EXT 180 | 305 | 215 | 665 | 275 | 270 | 135 | 370 | 135 | 565 | 230 | 270 | 200 | 475 | 35 | 200 | 315 | 10 | 20 |

| EXT 200 | 340 | 245 | 750 | 300 | 285 | 145 | 415 | 145 | 630 | 260 | 310 | 225 | 520 | 40 | 245 | 352 | 10 | 23 |

| EXT 225 | 385 | 260 | 825 | 340 | 300 | 125 | 470 | 165 | 705 | 270 | 320 | 250 | 570 | 45 | 245 | 352 | 10 | 23 |

| EXT 250 | 430 | 290 | 925 | 373 | 350 | 135 | 525 | 180 | 790 | 310 | 375 | 280 | 625 | 50 | 275 | 380 | 10 | 27 |

| MODEL | V | W | X | d1 | L1 | W1 | H1 | d2 | d2(MAX) | L2 | W2 | H2 | AVERAGE NET WEIGHT KG. |

APPROX. OIL CAPACITY LITRES |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EXT 110 | M16 | 180 | 8 | 25 | 50 | 8 | 28.5 | 35 | 40 | 85 | 10 | 38.5 | 70 | 3.500 |

| EXT 125 | M16 | 180 | 8 | 30 | 70 | 8 | 33.0 | 35 | 40 | 85 | 10 | 38.5 | 90 | 5.000 |

| EXT 140 | M16 | 240 | 8 | 35 | 70 | 10 | 38.0 | 40 | 55 | 140 | 12 | 43.5 | 125 | 6.000 |

| EXT 160 | M16 | 250 | 8 | 35 | 70 | 10 | 38.0 | 50 | 65 | 170 | 14 | 54.0 | 165 | 8.000 |

| EXT 180 | M20 | 265 | 8 | 50 | 100 | 14 | 53.5 | 55 | 70 | 170 | 16 | 59.5 | 240 | 10.500 |

| EXT 200 | M20 | 300 | 10 | 55 | 100 | 16 | 59.0 | 65 | 80 | 170 | 20 | 70.0 | 300 | 14.000 |

| EXT 225 | M20 | 300 | 10 | 60 | 100 | 18 | 64.0 | 65 | 85 | 240 | 20 | 70.0 | 400 | 17.000 |

| EXT 250 | M20 | 330 | 10 | 65 | 110 | 18 | 69.0 | 70 | 90 | 240 | 20 | 75.0 | 535 | 24.000 |

Extruder gear box Power Rating (kw)

| Power Rating kw | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ratio | Input Speed |

Output Speed |

Ext 110 |

Ext 125 |

Ext 140 |

Ext 160 |

Ext 180 |

Ext 200 |

Ext 225 |

Ext 250 |

||

| 6.3:1 | 1500 | 238 | 32 | 45 | 63 | 94 | 130 | 184 | 256 | 333 | ||

| 1000 | 158 | 21 | 30 | 42 | 63 | 90 | 130 | 193 | 252 | |||

| 10:1 | 1500 | 104 | 22 | 32 | 48 | 72 | 100 | 150 | 200 | 255 | ||

| 1000 | 69 | 15 | 21 | 32 | 46 | 65 | 95 | 135 | 170 | |||

| 12.5:1 | 1500 | 120 | 18 | 26 | 36 | 49 | 72 | 99 | 153 | 202 | ||

| 1000 | 80 | 12 | 17 | 24 | 33 | 46 | 69 | 103 | 148 | |||

| 14:1 | 1500 | 104 | 16 | 23 | 31 | 43 | 61 | 90 | 135 | 184 | ||

| 1000 | 69 | 10 | 15 | 21 | 28 | 41 | 63 | 94 | 130 | |||