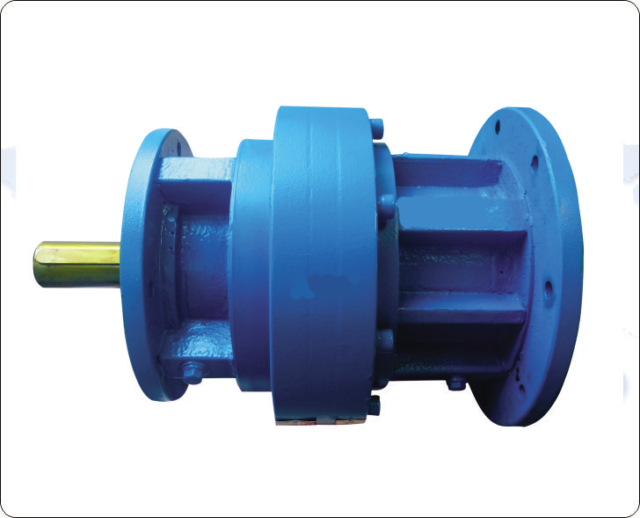

Planetary Gearboxes: The Powerhouse Behind Everyday Machines

Planetary gearboxes, sometimes called epicyclic gear trains, are those unsung heroes lurking within many of the machines that power our world. Despite their relatively small size, they play a critical role in multiplying torque (rotational force) and reducing speed, making them essential components in countless applications.

Unpacking the Planetary Gearbox

Imagine a miniature solar system working in perfect harmony. That’s essentially the concept behind a planetary gearbox. Here’s a breakdown of the key players:

- Sun Gear: The central gear, acting like the sun, receives the input rotation.

- Planet Gears: These smaller gears, orbiting the sun gear like planets, are housed in a carrier that rotates around the sun gear.

- Ring Gear: The outermost gear, similar to a ring around the planets, meshes with the planet gears.

How it Works: Multiplying Torque and Reducing Speed

The magic of a planetary gearbox lies in the way these gears interact. There are three main configurations, each achieving a distinct outcome:

- Sun Gear as Input: In this configuration, the sun gear receives rotation, while the ring gear is fixed. The planet carrier, along with the planet gears, rotates around the sun gear, resulting in a speed reduction and a torque increase at the output (typically on the carrier). This is the most common setup.

- Planet Carrier as Input: Here, the planet carrier is driven, while the sun gear is held stationary. The ring gear then rotates in the opposite direction of the carrier, resulting in a speed increase and a slight torque decrease at the output (typically on the ring gear).

- Ring Gear as Input: With the ring gear as the input and the sun gear fixed, the planet carrier rotates in the same direction as the ring gear, but at a reduced speed and with a torque increase at the output (typically on the carrier).

Why Use Planetary Gearboxes?

These ingenious gear systems offer several advantages:

- High Torque-to-Size Ratio: Planetary gearboxes can deliver a significant increase in torque within a compact package. This makes them ideal for applications where space is limited.

- Smooth and Quiet Operation: The meshing of multiple gears distributes load evenly, resulting in smoother operation and quieter noise levels compared to some other gear reduction systems.

- Versatility: The various configurations allow for both speed reduction and speed increase, making them adaptable to a wide range of applications.

- Durability: Planetary gearboxes are known for their robust design and ability to withstand high loads, making them reliable for long-term use.

Where Do We Find Planetary Gearboxes?

Planetary gearboxes are surprisingly ubiquitous. Here are just a few examples:

- Robotics: They are the driving force behind the precise movements of robotic arms and industrial automation systems.

- Power Tools: From drills and impact wrenches to angle grinders and power saws, planetary gearboxes provide the necessary torque and speed control.

- Automobiles: Planetary gearboxes are at work in automatic transmissions, differentials, and even window regulators.

- Wind Turbines: They play a crucial role in converting the slow rotation of wind turbine blades into high-torque output for electricity generation.

- Aerospace Applications: These gearboxes are essential components in aircraft landing gear retraction systems and other critical mechanisms.